.jpg)

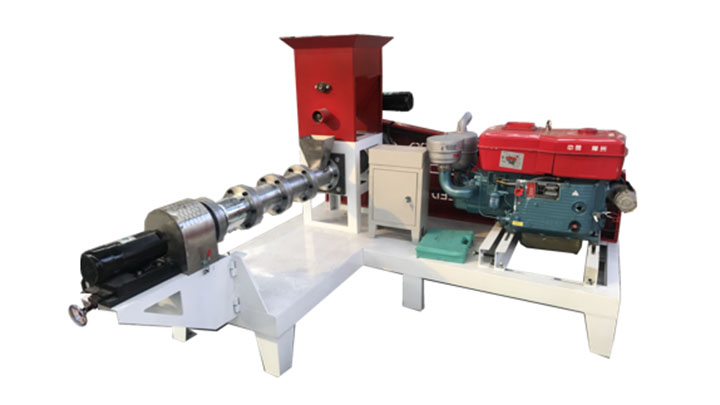

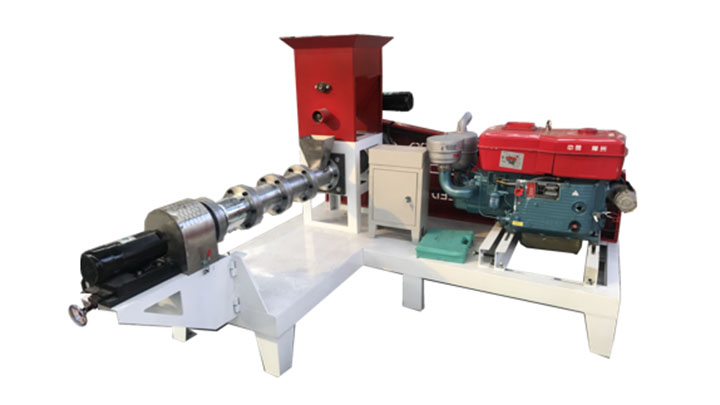

♦ Extrusion by fish feed extruder The fish feed extruder is a long barrel with a screw auger inside which is specially designed to subject feed mixtures to high heat and steam pressure. When feed exits the die at the end of the barrel, trapped steam blows off rapidly, the soft warm pellets expand, and a low density floating pellet is produced.

Oct 20, 2016 · Dry Type Fish Feed Extruder (1) Feed Hammer Mill (2) Feed Pellet line/plant (14) Feed Pellet Machine (9) Fish Feed Extruder (7) Fish Feed Machine (3) Fish Feed Pellet Machine/lines (4) Fish Feed Production Line (5) Floating Fish Feed Machine (3)fish Hammer Mill (3)fish Pellet line/plant (2)fish Pellet Machine (12)fish Pellet Production Line (9)

.jpg)

Applicable industries: Manufacturing Plant, Farms, Place of origin: Shandong, China, Voltage: According to your triple phase voltage,

Cost-efficient Fish Feed Machine of Top Quality. Introduction to Dry Type Fish Feed Extruder Dry type fish feed extruder, also called fish feed pellet mill, is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc.The final feed pellets have unique shape and good taste, high nutrition and smooth textures.

.jpg)

The proper extrusion of the raw material and the balanced formulation of nutrients improve the fish production till harvesting. High growth rate and low feed conversions improve the economical/financial results of the fish farmers. Our extruded feed is floating and allows the fish farmer to observe the behavior of the fish during time of feeding.

.jpg)

2. Application and features of Floating fish feed pellet extruder machine: 1. The finished pellets can keep floating more than 12 hours without pollution to water. 2. The floating fish feed pellet extruder machine can make pellet from Φ0.6 mm-20mm just by changing the mold. 7. Spare parts and package of the fish feed extruder mill: 8.

.jpg)

tilapia fish feed extruder manufacturer/supplier, China tilapia fish feed extruder manufacturer & factory list, find qualified Chinese tilapia fish feed extruder manufacturers, suppliers, factories, exporters & wholesalers quickly on LimaFeedPelletizer.com., page 2

Generally the compound feed of Tilapia are in two types: pelleted feed and extruded feed. To produce pelleted feed, the conditioning temperature should be controlled between 80-95℃. With sufficient conditioning period, good gelatinization can be achieved.

Generally the compound feed of Tilapia are in two types: pelleted feed and extruded feed. To produce pelleted feed, the conditioning temperature should be controlled between 80-95℃. With sufficient conditioning period, good gelatinization can be achieved.

.jpg)

1/11/2016 · Tilapia and Shrimp Feed Making in Brazil,Aquafeed making in Brazil,Tilapia feed,shrimp feed,feed formulation,fish feed extruder. Brazil is becoming one of majors aquaculture producers in worldwide, with significant advantages including the coastline of 8,500 km, 12% of the world’s freshwater reserves, tropical and subtropical

.jpg)

Feeding is as follows: twice a day, two periods: 8 a.m. to 9 a.m. and 3 p.m. to 4 p.m. Catch 30 to 50 fish every 15 to 20 days to calculate the average weight to analyze the growth of tilapia fish, which helps adjust feeding speed to help the fish grow healthily. Feeding speed also depends on the fish’s diet.

Apr 09, 2021 · Commercial tilapia feeds are formulated, cooked, extruded, and pelletized diets typically containing 32 – 40% protein. This can be a fish meal or soy-based protein, with the former being more palatable to the tilapia fish. Floating pellets are generally recommended, as they remain on the surface until consumed.

.jpg)

Special Design of Wet Type Fish Feed Extruder Parts. fish feed machine parts. Screw sleeve adopts Cost-efficient Fish Feed Machine of Top Quality Nov 28, 2018 - Dry type fish feed extruder, also called fish feed pellet mill, is widely used for producing variety materials into high-grade aquatic feed pellets for

.jpg)

Moreover, you can change extrusion degree to influence floating time. The fish pellet made by the machine can float on water more than 24 hours. Gelatinization degree can reach 90%. Brand Name:Loyal. Model Number:PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1 Place of Origin:Shandong, China.

.jpg)

3. Extrusion by fish feed extruder: under the pressure-tight condition, material in high temperature will be formed into pellets by shaping mould. Dry type feed extruder is popular in aquafeed production. 4. Drying: Final pellets from fish feed extruder are moist in high temperature, so use pellet dryer to remove moist and heat. 5.