.jpg)

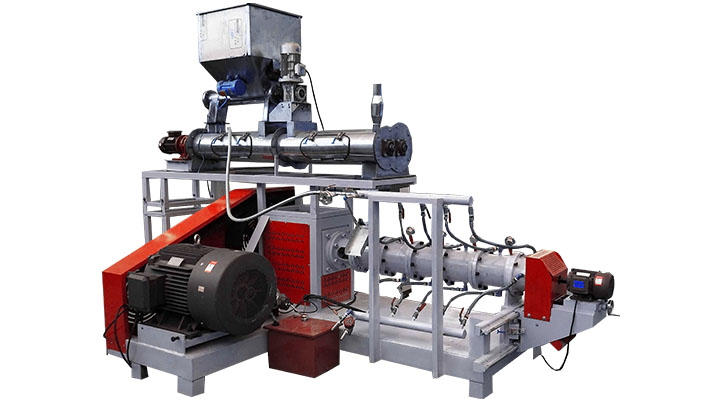

10/10/2017 · electric pellet machine is frequently driven by diesel engine or electric motor.Diesel feed pellet mill is energy saving pellet machine for making feed for animals such as feed for rabbits, fish, chicken, pigs, sheep, cattle, etc.A variety of raw materials like all grains such as corn, broomcorn, barley and wheat,etc.can be processed into feed pellets.Feed pelletizing process is

Generally the compound feed of Tilapia are in two types: pelleted feed and extruded feed. To produce pelleted feed, the conditioning temperature should be controlled between 80-95℃. With sufficient conditioning period, good gelatinization can be achieved.

.jpg)

c). Water quality: The extruded floating fish feed will not dissolve in the water for a long time. The floating time of high-quality floating fish feed can be as long as 12 hours, and it is easy to observe and control the bait, reducing or avoiding the . 400-500kg/h Floating Fish Feed Extruder Machine Fish Feed

Applicable industries: Other, Feed processing factory, Place of origin: Shandong, China, Voltage: 380v, Dimension(l*w*h): Tilapia fish feed machine extruder , floating fish feed processing line floating fish feed machine mill plant in Shandong, China

wet-way fish feed pellet extruder machine Malaysia-Lima Fish Reasonably Pfish feedd Fish Feed Pellet Machine in Nigeria. We provides wet type fish feed extruder at the pfish feeds+86 19337889051

At present, there are two kinds of artificial diets in tilapia feed, one is ordinary pellet and the other is extruded feed pellets. 0.75 to 1 kilograms tilapia feed produced by fish feed extruding machine can feed 0.5kg tilapia. In the production of ordinary pellets, the tempering temperature should be controlled between 80℃~95℃.

All tilapia feeds used in Malaysia are produces locally. 1.1.1.1 Suitable fish feed machine for quality commercial tilapia feed pellet production. LEARN MORE Producing tilapia feed locally: A low- cost option for small-scale

.jpg)

new design tilapia fish feed extruder for sale with easy-to-use parts graphics, giving you the ability to check parts availability, Castor Oil Plant Machine pricing, examine remanufactured 5.76 Inch | 146.304 Assembly Width options.

.jpg)

Applicable industries: Farms, Retail, Place of origin: Shandong, China, Voltage: 220V/380V, Dimension(l*w*h): 2200*1000*1500mm, Weight:

Tilapia Feed Formulation and Feeding - Fish Feed Extruder Feeding way will be the following: feeding twice in one day and two periods: 8am-9am and 3pm-4pm. Every 15-20 days, catching 30-50 fish to calculate the average weight for analyzing Tilapia growth, which contributes to adjusting feeding rate for helping fish grow healthily.

Feeding is as follows: twice a day, two periods: 8 a.m. to 9 a.m. and 3 p.m. to 4 p.m. Catch 30 to 50 fish every 15 to 20 days to calculate the average weight to analyze the growth of tilapia fish, which helps adjust feeding speed to help the fish grow healthily. Feeding speed also depends on the fish’s diet.

Jan 19, 2022 · CAD ArduToni. January 19th, 2022. Multifunctional Fish Feed Making Machine is a component / tool that serves to make or produce feed with various shapes and size. the workings of this machine is to process / stir the mixture of ingredients used for making fish feed in a processing container if all the ingredients are mixed evenly and then the

Farm-made feeds are not a major feed input in tilapia farms in Malaysia. They are made and used as supplement to commercial tilapia feed by small and medium sized tilapia farmers. In order to reduce feed production cost, farmers can choose dry type fish feed extruder to make own tilapia feed from local feed ingredients.

There are four main types of commercial tilapia feeds are available in Malaysia: pre-starter feeds, starter feeds, grower feeds and finisher feeds. All tilapia feeds used in Malaysia are produces locally. 1.1.1.1 Suitable fish feed machine for quality commercial tilapia feed pellet production. Commercial tilapia feeds are mostly extruded

.jpg)

Jul 01, 2022 · Floating fish feed pellets are desirable for tilapia which feed from the surface layers of water. Extruded feed pellets are more expensive due to the higher manufacturing costs. Usually, it is advantageous to feed a floating (extruded) feed, because the farmer can directly observe the feeding intensity of his fish and adjust feeding rates