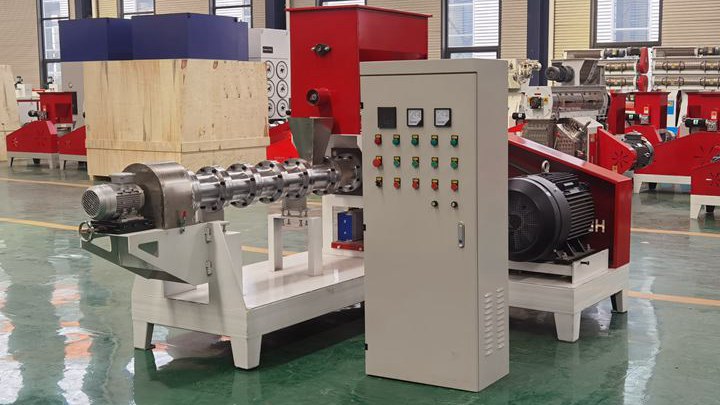

Fish Feed Machinery. Fish feed pellets are popular in modern commercial fish farming, providing balanced nutrition and improving fish farm environment. We provide dry type extruder, wet type extruder, single screw extruder, double screw extruder and diesel engine extruder, which can satisfy different production requirements. Feed Grinding Machine.

.jpg)

Flat die pellet machine; Feed pellet mill; Small pellet mill;fish crusher. 2 set XGJ850fish pellet line in Thailand. 3-5t/h Rice husk pellet line in Thailand.

.jpg)

SZLH350 hot sale feed pelletizing machine design with focus on high performance, reliability, feed hygiene, ease of maintenance, controllability, and low energy consumption. Complete range of belt-driven and gear-driven models available, matching any possible feed plant preference. Capacity: up to 8t/h.

.jpg)

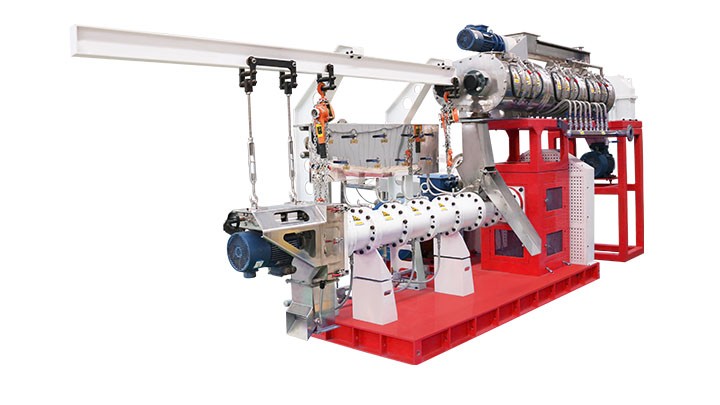

Thus Thailand has mastered the biomass pellet producing technology. Thailand importedfish pellet plant equipment is mainly from China pellet machinery factory. The wholefish pellet plant processing procedure includes material grinding, material drying, pelletizing, pellets cooling and pellets packaging.

.jpg)

Fish Feed Pellet Machine - HENAN YEARMEGA INDUSTRY Wet Type Floating Fish Feed Pellet Machine Wet type fish feed extruder works with a boiler which could continuously provide hot Tel:+86 19337889051

Animal Feed pellet machine also known as mold particle machine, can suppress the feed raw material to play a bactericidal effect, while killing the microbes while not affecting the quality of feed. I can according to the pig, cattle, sheep, chickens, rabbits, fish and other different growth cycle of the different nutrients needed to design the

.jpg)

The fish feed making machine was designed to make fish feed,pet feed,and other animal feed,it was taking meat meal, fish meal, bone meal, corn meal, soybean meal, grain flour etc. as the mainly raw materials. by changing fish feed recipe, temperature, molds and others, can produces fish pellet food in different shape,color.taste.The feed pellets produced by our fish feed production line have

.jpg)

As a professional feed pelleting machinery manufacturer and supplier, Lima Feed Machinery not only offers the single fish feed extruder machine, floating fish feed making machine, animal feed pellet machine, poultry feed production line for sale, but also provides the complete solution of setting up floating/sinking fish feed production lime, poultry feed production lines(50~10000kg/h).Lima

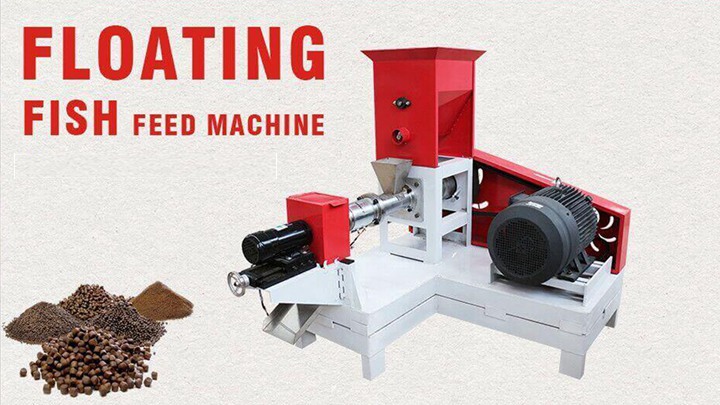

Aug 10, 2020 · New Arrival High Performance Floating Fish Feed Making Pellet Machine. Introduction Fish feed extruder line is widely used for producing grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. It also can make pet [read more] 2020-08-10 15:46:12.

.jpg)

Oct 20, 2016 · High Quality Steam Type Floating Fish Feed Pellet Machine, View High Quality Steam Type Floating Fish Feed Pellet Machine,US $ 2900 - 3100 / Set, ...

Detailed introduction. 1. Wet type floating fish feed machine, also known as fish feed extruder, is used to process various kinds of grains into high-grade aquatic feed pellets for fish, crab, catfish, shrimps, etc.

.jpg)

Uses/benefits: Hand-Operated Feed Pelleting Machine is recommended for producing feed pellets, especially for fish feed. It is used to convert feeds in mash form into smooth, strong pellets of 2mm, 4mm, 6mm depending on your need. The machine is simple in design and lightweight; and it is well recommended for small scale production of pellets.

The animal feed grinding machine has the advantages of small size, high efficiency, convenient operation and maintenance, simple process configuration, and low power consumption. Therefore, hammer type animal feed grinders are commonly used in animal feed processing. Email: enquiry@pellet-richi.com. WhatsApp: +86 138 3838 9622.

floating fish feed pellet making machine is single screw and dry type floating fish feed pellet machine which is mainly used to produce aquatic feed like for making fish feed,tilapia feed,catfish feed,shrimp feed,crab feed,turtle feed,goldfish feed and so on.the finished pellet feed are puffed by high temperature through the heating plate in the machine. so the finished pellet can be floating on water about 24 hours because of being puffed. and finished pellet size can be 0.9mm,1mm,1.5mm,2mm

High-capacity, modernized and biomass pellet machine design atLima.com for both residential and commercial uses. These pellet machine design are perfect for making sawdust pellets.