Tilapia Feed Formulation and Feeding Technique. Posted at 08:49h in Application. 38 Likes. Share. Different fish feed formulations can be made to satisfy Tilapia demands in different growth periods. Fish feeding should keep the rules: fixed time, fixed place, fixed quality and fixed quantity, and also consider four factors: season, weather

1-1.2t/h Dsp135 Fish Feed Extruding Line Machine For Making 1-1.2t/h DSP135 fish feed extruding line machine for making sinking fish and floating fish feed single machine:wood cas Tel:+8619337889051lima37@limamachinery.com

Fish Feed Extruder - Food Machinery Direct Sales Manufacturers200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which

.jpg)

Item no. Equipment list of fish feed extruder machine. Introduction of each part at fish feed production line. 1. Mixing machine. Mixing the material corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc.

Aug 01, 2016 · The selection, design, construction and testing of. the fish feed extruder for a fish farm were. undertaken. The extruder was tested and it wo rked. smoothly by producing pellets in the range 3

Apr 03, 2016 · One turnkey project for sinking fish feed plant in Saudi Arabia. Our client is one of the big in-land aquaculture operations in the world. We are proud to contribute to the progress of the aquaculture industry in Saudi Arabia. Our client purchased a turnkey extrusion line for producing 5 TPH sinking feed. All the steel structures, machinery, and control system are provided from Taiwan.

.jpg)

7/4/2019 · this type of floating fish feed extruder machine belongs to wet method type feed extruding machine for kinds of fish, which is specialized for big production capacity and big feed production factory, we also have another type of fish feed pellet machine for home use and small farm use.as per your requirement,you can choose to produce how much big of finished floating fish feed

.jpg)

40-800kg/h fish feed extruder, fish feed pellet machine for saleCapacity (kg/h): 40-800kg/h Finished Pellet: 1.5mm – 10mm Main Raw Materials: corn meal, wheat bran, soybean meal,

.jpg)

We produce our feeds in 2mm, 4mm and 6mm increments. o Feeds that are freshly produced with our extrusion, vacuum coating and pelleting process and state of the art equipment. With ARASCO fish and shrimp feed, you know you’re getting high performance out of your aqua farming enterprise. Read 5 reasons why you should feed ARASCO products to

Single-screw design has two types of fish feed extruders: dry type fish feed extruder and wet type fish feed extruder. The big difference between the “dry” and the “wet” extruder is: a dry extruder does not require an external source of heat or steam for injection or jacket heating that required by wet feed extruder.

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

Extruder for Animal Feed - Fish, Cats and Dogs. Extruder for Animal Feed - Fish, Cats and Dogs Main engine: 15kw | Cutting knife motor: 400w | Power motor: 400w | Production: 100-200kg/h | Machine dimensions: 1300x1200x1200mm | Machine weight: 500kgs

.jpg)

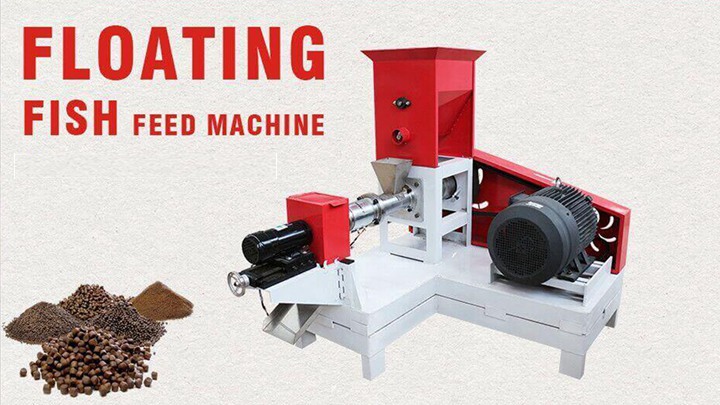

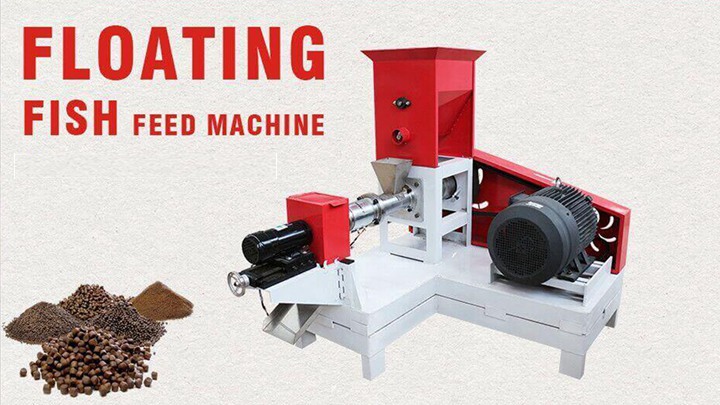

Floating Fish feed pellet machine By Dry Way. Model :LM70. Capacity (kg/h):50-200kg/h. Main power (kw):18.5kw. Feeder power (kw)0.4kw. Screw Diameter (mm):Φ70. Cutter power (kw);0.4kw. Machine size (mm):1650*1400*1300mm. Weight (kg):580kg.

.jpg)

11/10/2018 · The capability of an extruder enhances the feed manufacturer’s flexibility to produce fish feed pellets for shrimp, crab, eel, catfish, carp, frogs and etc.. 2.High starch gelatinization Feed material goes through the processing of HTST, starch gelatinization degree increase can reach 80-99% for aquatic animals easily digest.