200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

Dec 11, 2018 · Set up a Pet Food & Fish Feed Production Line.Lima machinery is a fish feed extruder machine manufacturer that specializes in the sinking fish feed, slow-sinking fish feed and floating fish feed processing technology. While improving the digestibility of the final feed for higher conversion, our fish feed machine is very economical.

Nov 28, 2018 · Extrusion Link and the Fish feed industry. Extrusion Link has been involved in the fish feed market since 2011 and has supplied 6 fish feed extrusion projects to companies in Vietnam, Greece and Northern Ireland. Our own EL100 has been the most popular extruder for fish feed. This midrange extruder designed by Extrusion-Link with custom dies

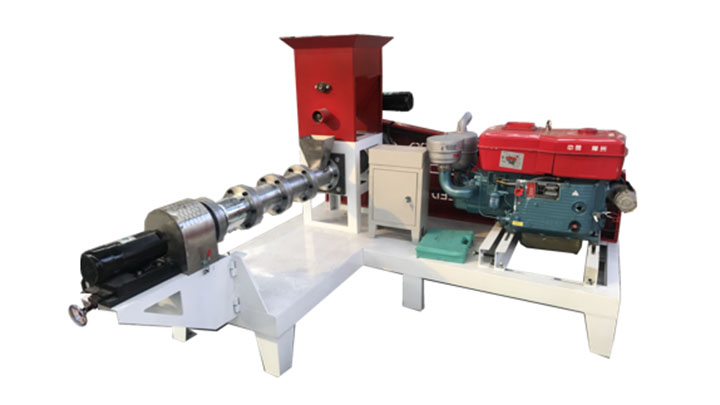

Dry Type Fish Feed Extruder - Feed Pellet MachineJul 21, 2020 · 1. Our fish feed extruder is of single screw design. 2. The pellets extruded from the fish feed pellet mill is abo

Lobe depositors and extrudersLobe depositors and extruders. Our technology effortlessly handles fluid, whipped or dense mixes and doughs with solid particles such as chocolate chi+86 19337889051

Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

100kg/h fish feed extruder design Feed size 1 mm Philippines Detailed introduction of the Sinking and Floating Fish and Dog Food Extruder 1. Sinking and Floating Fish Feed Extruder, also known as fish feed pellet machine, is used to process various kinds of grains into high-grade aquatic feed pellets for fish, crab, catfish, shrimps, etc. 2.

Buy the best and latest fish feed extruder on banggood.com offer the quality fish feed extruder on sale with worldwide free shipping. | Shopping New Zealand

.jpg)

Item no. Equipment list of fish feed extruder machine. Introduction of each part at fish feed production line. 1. Mixing machine. Mixing the material corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc. Are added with a certain proportion of water to mix thoroughly. 2.

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation. 2. Different molds can be chosen to make pellets with different diameters (0.9-15mm) and shapes. 3.

Single-Screw Fish Feed Extruder Design Single-screw design has two types of fish feed extruders: dry type fish feed extruder and wet type fish feed extruder. The big difference between the “dry” and the “wet” extruder is: a dry extruder does not require an external source of heat or steam for injection or jacket heating that required by wet feed extruder.

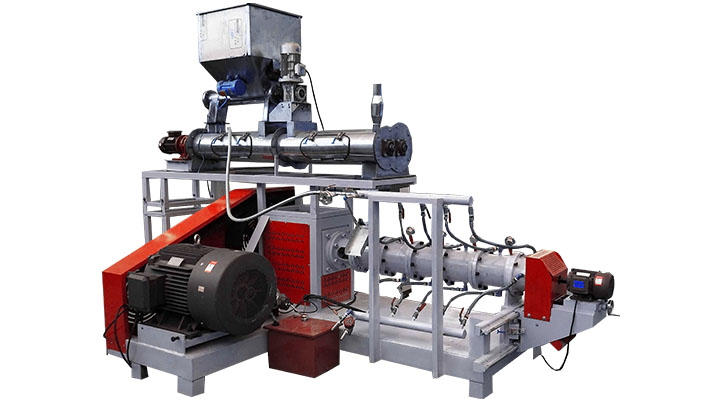

Model :LM80 Capacity (kg/h):200-300kg/h Main power (kw):22kw Feeder power (kw):0.6kw Screw Diameter (mm):Φ80 Cutter power (kw):0.6kw Machine size (mm):4000*2100*1900mm

Processing » Extruders » design extruder for produce fish feeds twin screw manufactured floating fish feed extruder machine in Shandong, China ‹ ›

The fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made. Fish feed extrusion systems | ClextralClextral provides a wide range of twin-screw extrusion fish feed machines. It has played a pioneering role in the innovation and development of

.jpg)

factory Mackerel fish feed extruder machine nepalFloating Fish Feed Machine - Feed Extrusion Machinery4.5*1.2*2.3m. LZ3000-100. 46KW. 30KW. 60-100kg/h. 3.2*1.1*2m.