Sep 05, 2016 · Hot Dry-type feed making machine & wet type fish feed extruder 1.Application: The machine is widely used for process all kinds of grains into high-grade aquatic floating feed pellets for

.jpg)

Best selling CE Approval 6-10t/h poultry feed pellet making machine for sale, US $ 22484 - 22584 / Set, Manufacturing Plant, Farms, Feed Factory, Egypt, Canada

7/4/2019 · this type of floating fish feed extruder machine belongs to wet method type feed extruding machine for kinds of fish, which is specialized for big production capacity and big feed production factory, we also have another type of fish feed pellet machine for home use and small farm use.as per your requirement,you can choose to produce how much big of finished floating fish feed

2021 motor engine fish feed extruder machine for sale,Fish feed making machine is also named fish feed extruder, and it is used for processing for dogs and cats (pet food), birds, piglets, frogs, sinking and floating aquatic feeds for fish. Which is high and new technical program as to catch the developing pet food market.

Fish feed extrusion is a process that uses high temperature and pressure to cook fish feed ingredients. This process results in a more expanded feed that is easier for fish to digest. In this post, we will discuss the benefits of fish feed extrusion, as well as its specifications and its many uses!

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet

200kgh fish feed extruder machinefloating fish feed extruder machine. Manufacturer: Ainuok; fish feed extruder machinefloating fish feed extruder machine Machine Product Description 1.Floating rainbow trout shrimp guppy cat fish fish feed pallet machine uses corn, soybeans (bean cakes), animal scraps, et

Aug 01, 2016 · The selection, design, construction and testing of. the fish feed extruder for a fish farm were. undertaken. The extruder was tested and it wo rked. smoothly by producing pellets in the range 3

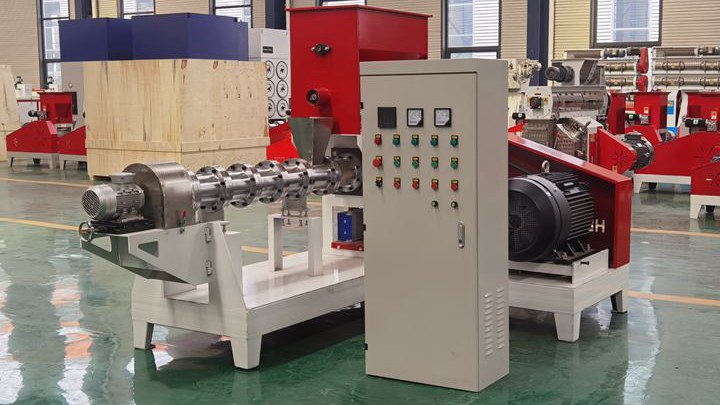

Twin screw extruderInlcuding wet twin screw extruder, pre-conditioner, control boxFloating fish feed integralType: SP200SCapacity (KG/h): 100-200 (according

floating fish feed extruder machine, floating fish 2273 products - Henan HeXie Machinery Co., Ltd..com offers 2273 floating fish feed extruder machine products. About 60% of these are Feed Processing Machines, 0% are Plastic Single Screw Feed Extruders for Floating Fish Feed or Pet FoodSpecial Design of Wet Type Fish Feed Extruder Parts. fish

200-300kg/h. Dimensions. 18*1.3*2.4. Our factory produces a complete set of production equipment for fish feed, which produces fish feed with novel shape, unique taste, rich nutrition and delicate organization. If you need to buy, or want to know more about feed extrusion equipment, please contact us.

Qualified Fish Feed Extruders and Feed Production Line by Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditio Tel:+8619337889051lima37@limamachinery.com

If you have requirements for a larger capacity, we have the fish feed production line available. Welcome to contact us for more clarifications! floating fish food machine-DGP-40 fish pellet making machine-DGP-60 fish food manufacturing machines-DGP-70 dry type fish feed extruder-DGP-80 animal feed pellet mill-DGP-100

As the professional fish feed making machine manufacturer ,our fish feed extruder machine design good manufacturing process . fish feed extruder machine can take corn flour, soybean meal, starch, fish meal and others as raw materials,to make the high protein-fish feed pellet&floating fish feed pellet .catfish feed,pet food .bird feed for sale.

Jun 01, 2019 · The throughput is the rate at which the feed sample fed into the machine is been recovered. This was obtained using Eq. (20). In this work, 3 kg of the homogenous feed mixture was fed into the machine and 2.2 kg of the feed was recovered at a time interval of 8 min.