.jpg)

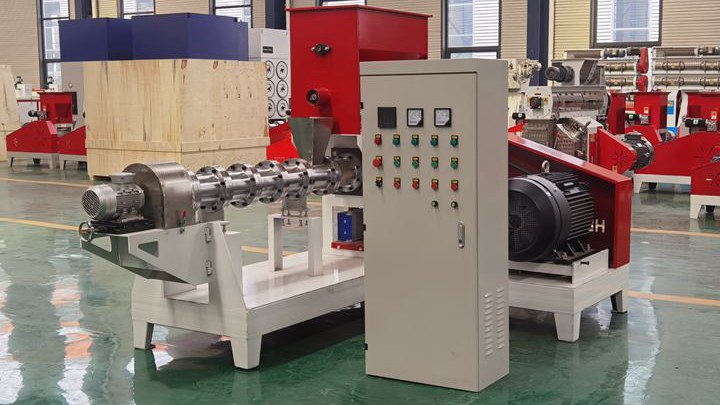

Extruder Machine In Zambia. If you are looking for verified Extruder Machine suppliers in Zambia, then Getatoz is your one-stop solution. Browse Extruder Machine manufacturers, suppliers and exporters of Zambia. Getatoz has curated a list of the Extruder Machine suppliers who are among the best in the market.

Design and fabrication of a modified fish feed pelletizing Fish feed pelletizing machine was designed and fabricated with the aim to improve on existing local pelletizers; encoura+8619337889051 Email:lima37@limamachinery.com

.jpg)

As a kind of feed making machine, the wet type fish feed extruder can make fish feed pellets from corn, bean pulp, corp stalk, grass, rice hull and so on. The wet type fish feed extruder machine is widely used in making both floating fish feed and sinking feed pellets for aquaculture farms, feed mills, livestock farms and poultry farms.

May 23, 2007 · 260. Post Thanks / Like. Contact local feed store and you may have to call around to different ones and ask for fish meal in 50 lb. bags. Catfish food pellets will work too. Use floating pellets because you can see them eating food to make sure they are eating what you put in.

.jpg)

Aug 04, 2015 · The facility will have an initial capacity of 25,000 tonnes per annum with modular design enabling ease of expansion up to 50,000 tonnes per annum. This capacity is expected to meet Yalelo’s own feed requirements along with those of other aquaculture farmers in the growing Zambian aquaculture sector. At the centre of the mill will be the Famsun MY120 twin-screw extruder with capacity of 7.5 tonnes per hour and the new 3000 Series Famsun dryer.

.jpg)

As they mature and reach adulthood, they still consume insects and aquatic shrimp, tadpoles, and crayfish but their diet evolves to feeding mostly on baitfish. Crappie readily consume small bluegills, small yellow perch, small bass, along with shiners, suckers, small shad, and minnows. The best bait for crappie are fathead minnows.

Fish fed type 2 feed outperformed fish fed type 1 feed in final biomass, percent gain and SGR. Feed conversion ratios on an as fed basis were 1.99, and 1.82, for black crappie fed type 1 and type 2 feed and 1.88, and 1.60 for white crappie fed type 1 and type 2 feed, respectively.

Extruder for Animal Feed - Fish, Cats and Dogs. Extruder for Animal Feed - Fish, Cats and Dogs Main engine: 15kw | Cutting knife motor: 400w | Power motor: 400w | Production: 100-200kg/h | Machine dimensions: 1300x1200x1200mm | Machine weight: 500kgs

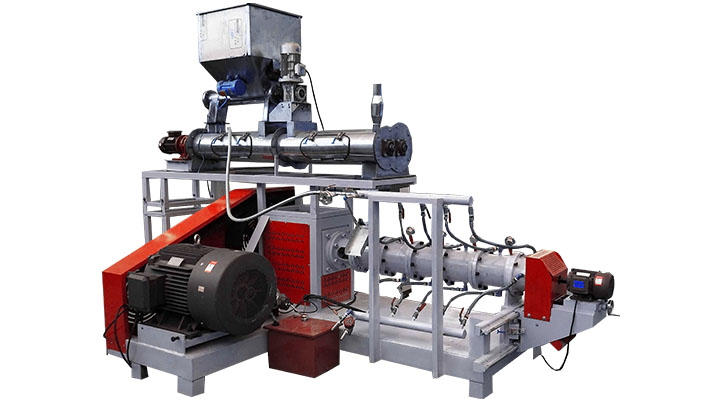

Sep 16, 2017 · Dry Type Fish Feed Extruder. Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

1) They are temperature hardy for all of north america, 2) They are one of the best tasting freshwater fish. 3) I expect them to be more active/feed for a longer portion of the year than say bluegill and channel catfish. Cons, 1) potential obstacle in getting them to eat commercial feed.

Jul 27, 2021 · IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre

.jpg)

Jan 27, 2018 · Crappie are like other predator fish. They will suspend and eat bait grouped in balls and the crappie school to feed on them. The crappie have eyes that naturally look forward and up while standing still. They hang below or to the sides of these bait balls. Never above as they don't look down without putting the tails in an up postion which is

Apr 21, 2022 · Tip: using fish feed extruder produce (sinking and floating) feed pellets by own, all of above requirements can be met. III.Feeding Method of Freshwater Fish The goal of feeding in pond is to feed the fishes with required quality, quantity, and feeding time per day. So as to achieve the best production effect and benefit.

.jpg)

What is Fish Feed Extrusion Process. Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet

Dec 08, 2021 · Mr Chisanga was trained to be a hatchery operator in 2020 and provided with 100 fish, four hapas, one net, four bags of commercial fish feed and other materials to help him manage his new business