To processing feed pellet for fish,dog,cat,brids, catfish feed etc. Type: Floating feed pellet making extruder fish feed manufacturing machine: Power Source: Electric: After-sales Service Provided: Engineers available to service machinery overseas, Online support: Application: Fish feed making machine: Material: 304 Stainless Steel: Capacity

Generally speaking, fish feed production process flow has several main steps, including procurement of feed ingredients, raw materials grinding, mixing, extruding, drying and automatic weighing and packaging, in tune with scientific and nutrient aquatic feed formulation. Acquisition of feed ingredients. According to nutritional requirement for

Catfish feed production method: Weigh all feed stuffs – fully grinding all raw materials via fish feed grinder machine – pass through 50 mesh for screening – mixing – extrusion. Notice: 1. All feed stuffs should be cleaned before grinding, if not, impurities of feed stuffs would lower catfish feed quality and even damage the fish feed

The physical feed quality is critical in enabling the feed to provide the desired nutrition and energy to the fish. Some of the common quality issues are feed integrity, non-uniformity of feed sizes, unable to attain the desired level of floatability (in case of floating feeds), dust creation from feeds, oil leakage, rancidity issues, and raw material quality.

Mar 26, 2022 · Reasonable price will be given according to your needs. We mainly produce fish feed extrusion machine, artificial rice machine, puffed snacks machine, pet food machine, etc. If interested, please feel free to contact me. My whatsapp: +86 176 8668 2883 / +86 186 6376 4200. My email: lead@sunpring.com.

.jpg)

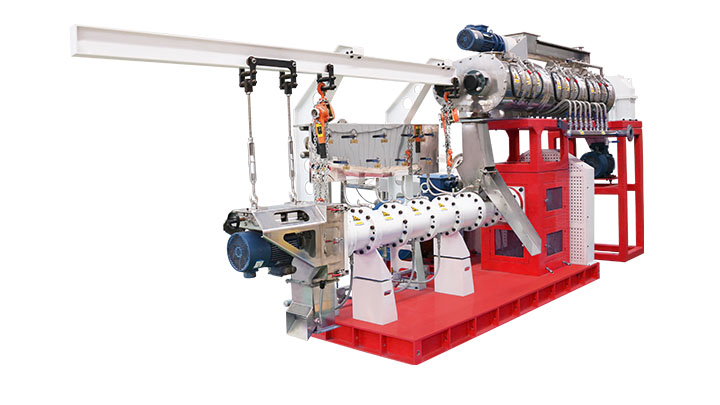

The wet type fish feed extruder machine has character of high yield, good quality and long service life of wearing parts. Generally speaking, the service life of wet type is about twice than that of the dry type fish feed extruder. Dry type extruder machine is suitable for small manufacture and fish farm. 4. Drying Technology

.jpg)

Jul 06, 2022 · Catfish feed extruder Manufacturers & Suppliers, China catfish feed extruder manufacturer/supplier, China catfish feed extruder manufacturer & factory list, find qualified Chinese Tel:+8619337889051lima37@limamachinery.com

high efficiency fish feed plant types of asphalt mixing plant ECA Self-movable mobile plant. 30 to 120 m 3 /h; EBA Mobile plant for medium productions. 30 to 70m 3 /h; EMA Compact Tel:+8619337889051lima37@limamachinery.com

.jpg)

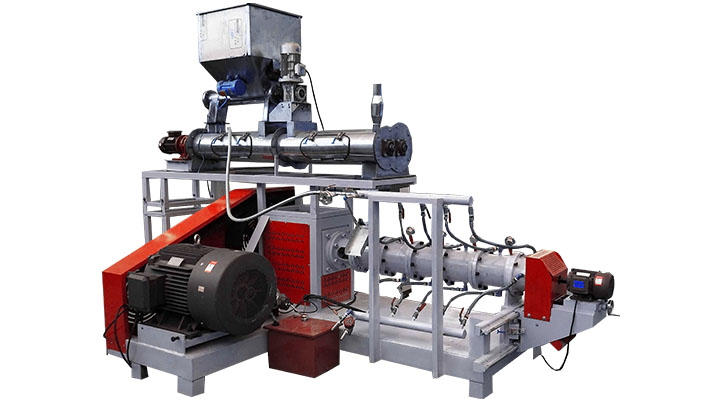

Single-screw design has two types of fish feed extruders: dry type fish feed extruder and wet type fish feed extruder. The big difference between the “dry” and the “wet” extruder is: a dry extruder does not require an external source of heat or steam for injection or jacket heating that required by wet feed extruder.

.jpg)

Uganda Trout Catfish Aquarian Soybean Flour Grain Formulation Sinking Fish Feed Granulation Extruded Machine Henan Hanson Industry Co., Ltd. 1 Set (Min. Order)

.jpg)

It is best to feed 38% of the protein feed to the smallest species in the form of crumbs. Fish about 3 inches long can take advantage of 3/16 inch floating particles with a protein content of 35 to 36 percent. When a catfish species is placed in a pond, there are more options for feed quality. One of the more recent options was to feed a lower

.jpg)

Dry-type fish feed extruder is adopted to process various kinds of grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab, etc. Final pellets produced by fish feed extruders have a unique shape, good taste, and balanced nutrition. It is the ideal device for small and medium-size feed processing plants and aqua-farms.

Novel and unique design, simple structure, easy to install and disassemble, easy to operate. 3. The screw sleeve and screw are made of special wear-resistant and high-temperature alloy steel materials, formed by heat treatment, wear resistance and long service life.

.jpg)

Sep 16, 2017 · Dry Type Fish Feed Extruder. Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

Catfish fry in hatcheries are fed finely ground diets or flour-based feeds containing 45-50% protein. Once the fish are in the pond, they are usually fed a diet containing about 40 percent protein. Some producers feed “fish” with 28 or 32 percent protein, and the food fish grow until they grow to 1-2 inches.