Catfish fry and their density. Select quality catfish fry (small fish) of 2 to 3 inches in size from the fish farm. Selecting small, high-quality, disease-free, high-yielding catfish is essential for successful catfish farming. Stock the fry in the pond for 3 days and then spray the pond with antifungal medication to prevent any diseases.

.jpg)

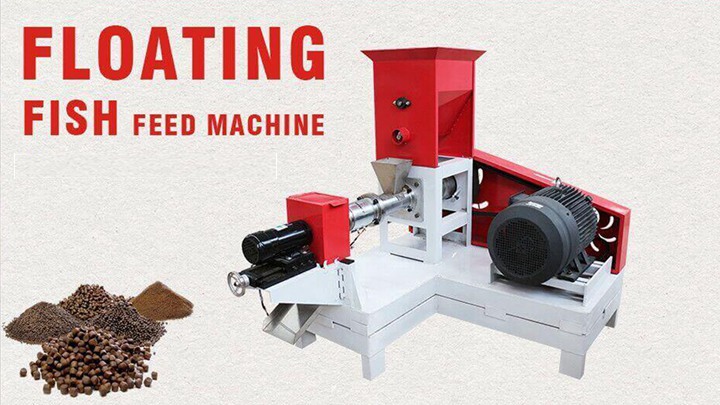

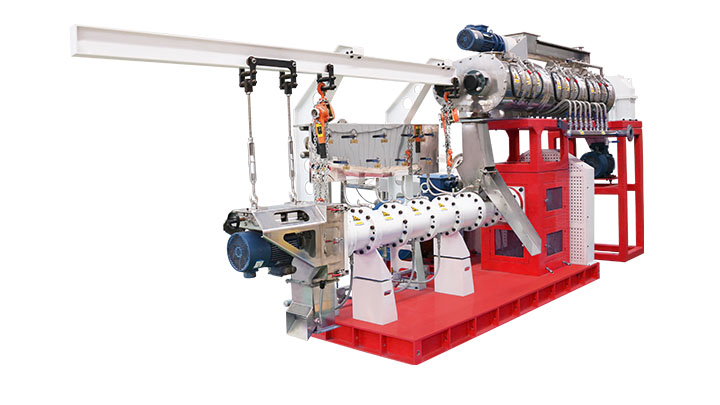

As a floating fish feed extruder machine manufacturer, in order to meet floating and sinking fish feed, feed Production Line supplier developed twin screw extruder design, is widely used for produce high-grade aquatic feed pellets for fish, catfish, shrimp, crab, lobsters, etc.Food extruder production process can produce both floating and

.jpg)

Screen sizes recommended are as follows: for 2mm pellets, 0.75mm; for 3-5mm pellets, 1.0mm; for bigger pellets, 1.0-1.25mm. 2. Mixing technology. Next, place all the ingredients in a blender, and then add about a teaspoon of garlic powder before blending the whole mixture.

Floating Carps Catfish Koi Fish Feed Processing Extrusion Making Machine , Find Complete Details about Floating Carps Catfish Koi Fish Feed Processing Extrusion Making Machine,Floating Fish Feed Making Machine,Koi Feed Processing Machine,Catfish Feed Making Machine from Feed Processing Machines Supplier or Manufacturer-Jinan Kelid Machinery Co., Ltd.

.jpg)

The floating fish feed pellet machine/fish food machine can make kinds of feed for different fishs, such as food fish, catfish, shrimps, crab, eet, etc. the

Fill the barrel. Make sure the faucet, valve or stopper is sealed, then pour ordinary tap water or hose water into the barrel. Fill it until the water is between 6-8 inches from the top of the barrel. This space will help minimize the chance of catfish jumping out of the barrel and the ground below.

.jpg)

Catfish Fish Meal Floating Feed Extruder Machine_OKCHEMCatfish Fish Meal Floating Feed Extruder Machine_OKCHEM Please note that all emails sent by OKCHEM are from ***@okchem.com, Tel:+8619337889051lima37@limamachinery.com

.jpg)

Catfish feed production method: Weigh all feed stuffs – fully grinding all raw materials via fish feed grinder machine – pass through 50 mesh for screening – mixing – extrusion. Notice: 1. All feed stuffs should be cleaned before grinding, if not, impurities of feed stuffs would lower catfish feed quality and even damage the fish feed

Mar 26, 2022 · Reasonable price will be given according to your needs. We mainly produce fish feed extrusion machine, artificial rice machine, puffed snacks machine, pet food machine, etc. If interested, please feel free to contact me. My whatsapp: +86 176 8668 2883 / +86 186 6376 4200. My email: lead@sunpring.com.

ECA Self-movable mobile plant. 30 to 120 m 3 /h; EBA Mobile plant for medium productions. 30 to 70m 3 /h; EMA Compact plant, perfect for prefabricated. From 30 to 100 m 3 /h; MODULMIX Plant for large productions and special concretes. 80 to 150 m 3 /h

Sep 16, 2017 · Dry Type Fish Feed Extruder. Dry type fish feed extruder is the the specialist contributing to high quality floating fish feeds without steam conditioning of the raw material. Different molds are available to make pellets of different diameters (0.9-15mm) and shapes.

.jpg)

It is best to feed 38% of the protein feed to the smallest species in the form of crumbs. Fish about 3 inches long can take advantage of 3/16 inch floating particles with a protein content of 35 to 36 percent. When a catfish species is placed in a pond, there are more options for feed quality. One of the more recent options was to feed a lower

Uganda Trout Catfish Aquarian Soybean Flour Grain Formulation Sinking Fish Feed Granulation Extruded Machine Henan Hanson Industry Co., Ltd. 1 Set (Min. Order)

1. Technology paramter of fish feed extruder pellet machine Materials for dog/cat/fish food: wheat/ corn flour, fish meal, born powder, animal oil 2, Final food : different shapes and sizes of dog food, cat food, shrimp feed, fish feed, poultry feed 3, Capacity: 100-160kg/h, 200-260kg/h, 400-500kg/h, 800-1500kg/h, 2-3t/h, 4-6t/h

Small Animal Floating Fish Feed Pellet Making Extruder . Animal feed making machine can be widely used to produce dog, cat, shrimp, fox,bird and pet food production.Base on the market demand,to do R&D of animal feed production line for various models and settings.By adjusting raw materials,temperature,moisture and other technical parameters, to make our products with characteristics of unique