-

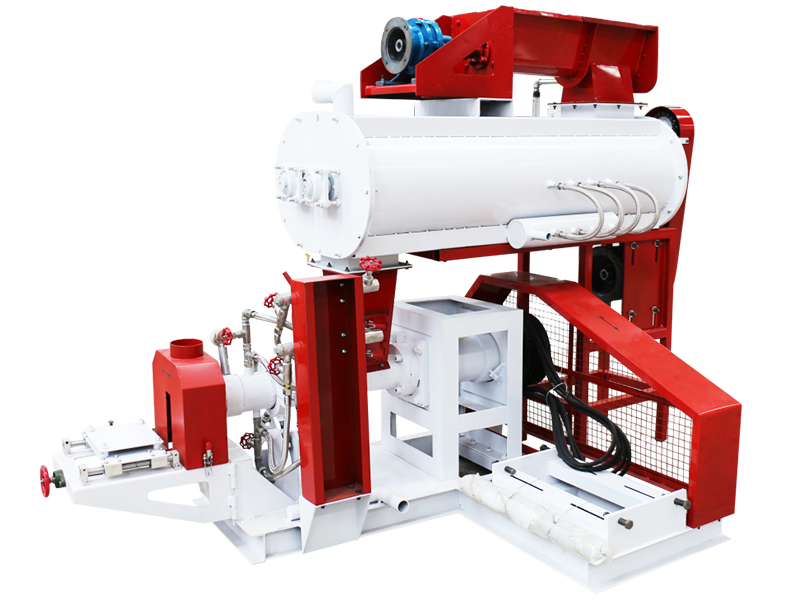

Floating Fish feed pellet machine By Wet Way

Model :LM90-B

Capacity (kg/h):500kg/h

Main power (kw):37kw

Feeder power (kw)1.1kw

Screw Diameter (mm):Φ90

Cutter power (kw);2.2kw

Machine size (mm):2600*2100*1900mm

Weight (kg):800kgMore -

Floating Fish feed pellet machine By Diesel Engine

Model :LM70-Diesel

Capacity (kg/h):80-200kg/h

Main power (kw):30HP

Feeder power (kw)0.4kw

Screw Diameter (mm):Φ70

Cutter power (kw);0.4kw

Machine size (mm):1650*1400*1300mm

Weight (kg):650kgMore -

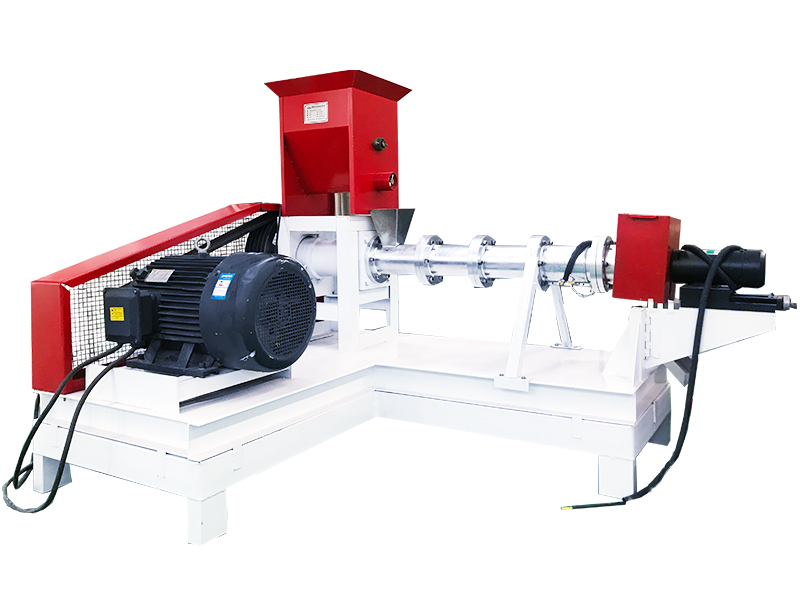

Floating Fish feed pellet machine By Dry Way

Model :LM70

Capacity (kg/h):50-200kg/h

Main power (kw):18.5kw

Feeder power (kw)0.4kw

Screw Diameter (mm):Φ70

Cutter power (kw);0.4kw

Machine size (mm):1650*1400*1300mm

Weight (kg):580kgMore

.jpg)